Plastic injection moulding provides tight tolerances and repeatability and is ideal for high volume production of plastic moulded parts. Injection-moulded plastic parts can be manufactured using a wide range of thermoplastic polymers, resins and elastomers, making it an ideal and cost-effective process for various industries and applications.

Injection moulded parts are created by pouring raw plastic resin into a hopper, then heating the resin and injecting it into a custom mold. Pressure is used accommodate shrinkage and once the plastic molded part has fully cooled, the mold is opened, and the parts are removed. Because of the tight tolerances, plastic injection molding is a suitable option for both standard and intricate plastic molded parts of all sizes.

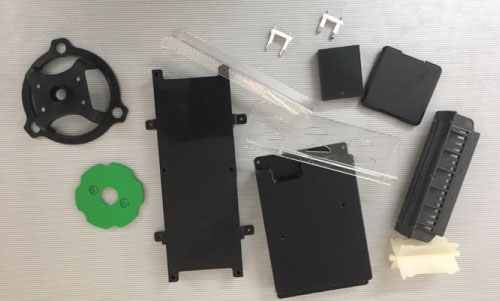

Dev Moulders specializes in custom plastic injection molding (or “moulding”) and provides services for industries including aerospace, medical and consumer products, electronics and home appliances. With our precision injection molding capabilities, we can create thousands or millions of identical parts. From simple to complex designs for parts between 0.5 g and 500 gms., we deliver precision plastic injection molding to match your unique specifications.